Our specialists selected and adapted the best instruments to make them work together with reliable process. You can find here a short description of the equipment. Please don’t hesitate to contact us to have more information and keep in mind that we have several model to fit for the best your needs.

SU-8模具制造站,SU-8厚胶制作系统,,SU-8厚光刻胶制作系统,SU-8光刻台式工作站

型号:SU-8

联系人:李胜亮

联系电话:18618101725

品牌:darwin

SU-8模具制造站,SU-8厚胶制作系统,,SU-8厚光刻胶制作系统

——wu需洁净室中,创建自主的SU-8模具

我们的SU-8光刻台式工作站包括您在实验室中制造微流体模具所需的一切,其分辨率和效率与洁净室相同。 一切都可以缩短过程,并在您的微流体研究中快速自主。

一个交钥匙式的(Turnkey)工作站,用于制造您的SU-8微流体模具!

优点:

达到与洁净室相同的图案分辨率

获得强光刻胶图案,适用于未来的众多PDMS模塑产品

使用可实现轻松再现性的强大流程

在没有微细加工初步知识的情况下制造模具

获得zui佳设备,确保您的设施使用寿命长

套装设备包括:

- 数码热板

- 紫外灯系统

- 可编程旋涂机

- 配件和化学品

all化学品(SU-8,SU-8显影剂,Omnicoat,异丙醇,丙酮等)和all实验室配件(微量移液器,定时器,玻璃器皿,封口膜,镊子,dimaond刮刀,晶圆,载玻片,培养皿,一次性杯子, 包括搅拌棒,手术刀等),以便为您提供zui完整的套装。

化学品 - 微流体-SU8-显影剂 - 异丙醇 - 丙酮-TMCSAccessory-微流体-PDMS成型

售后支持

标准支持包:我们负责all仪器的售后服务,我们为您提供微加工工艺表和教程,我们为您提供1年的电话帮助,以解答您可能遇到的任何微加工问题。

扩展支持包:除标准包外,我们的研发团队直接在您的实验室中安装softlithobox,我们根据您的需求调整我们的all微加工流程,我们培训您的团队,直到准备好制作您的all微流体芯片。

SPIN COATER

This spin coater is compact and packed with advanced features. It works with wafer up to ?150mm and 5″ × 5″ (127mm × 127mm) substrates. This spin coater is perfectly fine-tuned to do controllable and repeatable Su-8 photoresist layer.

A device adapted for Soft-lithography applications

Its compact size with the little panel control attached make the device really movable. The product has been widely use for SU-8 photoresist coating. The hole on the lid enables to do dynamic SU-8 coating. Easily connected to PC via Bluetooth, you can saved and named your recipe.

Major strengths:

- Designed specifically for ease-of-use

- Simple to program from the operator panel or your PC

- Ability to set complex sequence with several accelerations and speeds

- Non clogging system for extended lifetime

- Low vibration

- Speed up to 12000 rpm

- Provided with wafer centering tool

UV LAMP SYSTEM

An unique UV LED exposure and masking system (in option) with available light sources at wavelengths of 365 nm or 385 nm. This is a very compact table-top system capable of exposing a wafer surface area of up to 4 inches in diameter. This automatic UV system is compatible with hard (physical) or soft (proximity) masking contacts, and features variable mask to substrate distance control.

An unique UV LED exposure and masking system (in option) with available light sources at wavelengths of 365 nm or 385 nm. This is a very compact table-top system capable of exposing a wafer surface area of up to 4 inches in diameter. This automatic UV system is compatible with hard (physical) or soft (proximity) masking contacts, and features variable mask to substrate distance control.

A device adapted for Soft-lithography applications

With 2μm resolution, the device is particularly well tuned for soft-lithography applications. The exposure in flash enables to reduce the internal mechanical stress of the photoresist. Its little size enables to install it everywhere you want, especially outside a clean room.

Major strengths:

- Perfectly monochromatic exposure over the wafer surface area (bandwidth lower than 10 nm)

- Cold UV exposure

- Divergence angle of the light < 2°

- Strong power density

- Long LED lifetime: more than 10 000 hours equivalent to 8 – 10 years of use

- User-friendly touch screen interface for exposure cycles programming

- No warm-up time required

- Intuitive control of UV source intensity

- Automated wafer loading and unloading system

- Usable with glass and plastic photomask

- High UV uniformity on 4 inches wafer

- Integrated UV meter

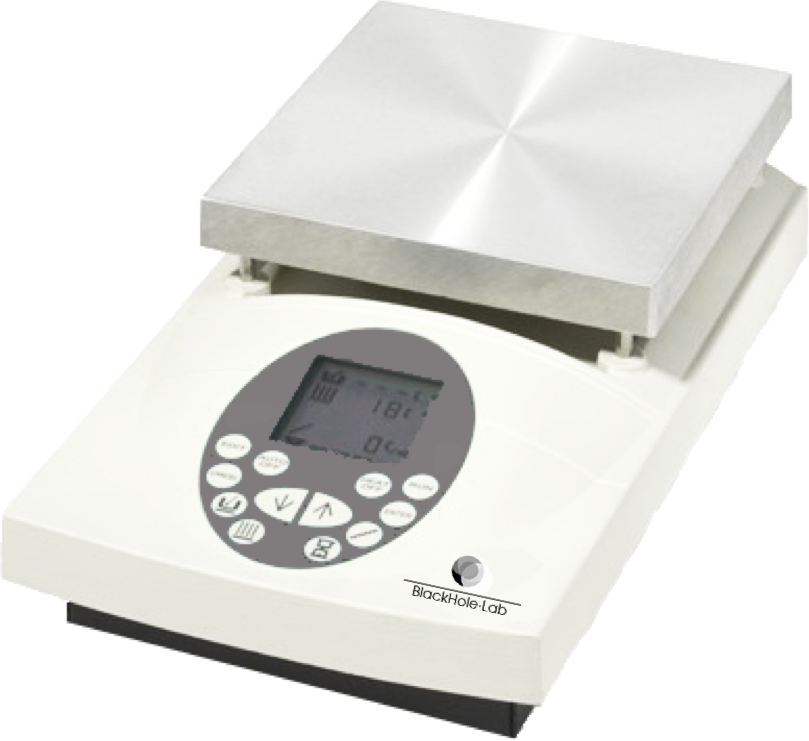

PROGRAMMABLE HOT PLATE

Ensure accurate, homogeneous and stable temperature set points. This digital hotplate device enables to set temperature ramp for heating and cooling down. Make your life easier with its programmable controls which enable to automatize your photolithography process.

Ensure accurate, homogeneous and stable temperature set points. This digital hotplate device enables to set temperature ramp for heating and cooling down. Make your life easier with its programmable controls which enable to automatize your photolithography process.

A device adapted for Soft-lithography applications

Its aluminum top plate and its great heating surface area enables to have a wide enough zone where the temperature is homogeneous for an efficiently bake of SU-8 photoresist on a 4 inches wafer. The temperature ramp enables to reduce the mechanical stress inside the photoresist layer. The programmable tool enables to do long photoresist bakes without staying in front of the device.

Major strenghts:

- Temperature ramp to heat up and cool down.

- High temperature uniformity over 4 inches wafer

- Microprocessor display maintains consistent temperature

- Minimal temperature overshoot

- Automatic timer

- Smoothed aluminium plate for easy photoresist cleaning